The Material Characteristics of Silicon Carbide

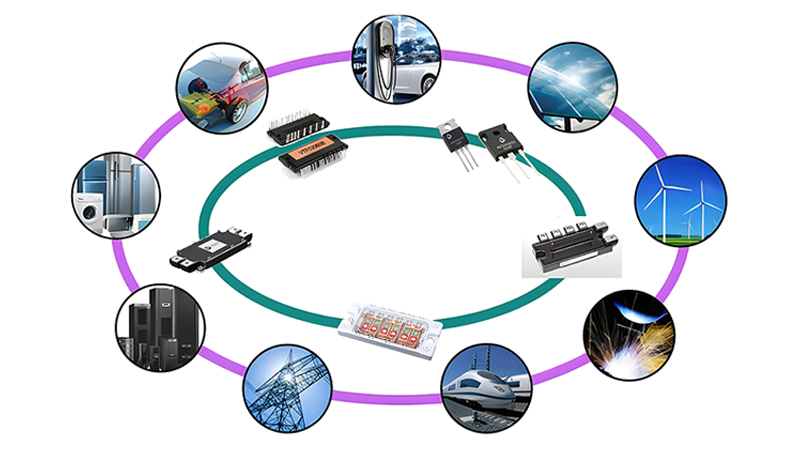

Due to its stable chemical properties, high thermal conductivity, low thermal expansion coefficient, and good wear resistance, silicon carbide has many other uses besides being used as an abrasive. For example, by applying silicon carbide powder to the inner wall of a water turbine impeller or cylinder body through a special process, its wear resistance can be improved and its service life can be extended by 1-2 times; The advanced refractory material used for production is heat-resistant, shock resistant, small in size, lightweight, and high in strength, with good energy-saving effects. Low grade silicon carbide (containing about 85% SiC) is an excellent deoxidizer that can accelerate steelmaking speed, facilitate chemical composition control, and improve steel quality. In addition, silicon carbide is also widely used in the production of silicon carbon rods for electric heating components.

Silicon carbide has a high hardness, with a Mohs hardness of 9.5, second only to the world's hardest diamond (grade 10). It has excellent thermal conductivity and is a semiconductor that can resist oxidation at high temperatures.

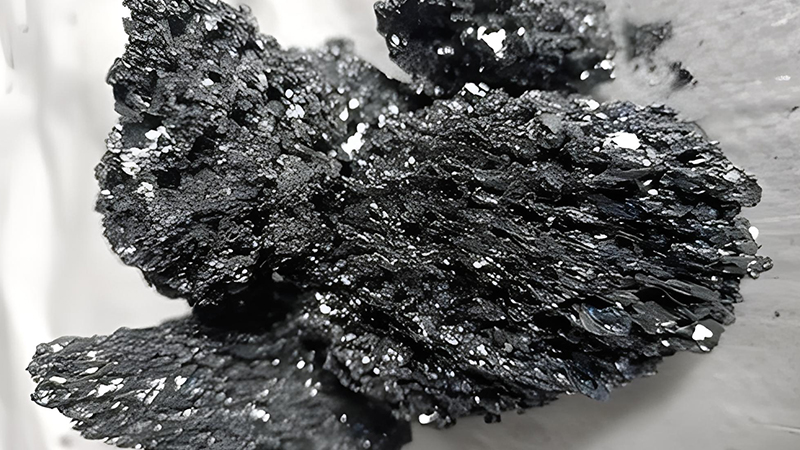

Silicon carbide has at least 70 crystalline forms. α- Silicon carbide is the most common type of isomorphic material, formed at high temperatures above 2000 ° C, with a hexagonal crystalline structure (similar to fibrous zinc ore). β- Silicon carbide, with a cubic crystal structure similar to diamonds [13], is formed below 2000 ° C. In the application of heterogeneous catalyst carriers, β- Silicon carbide due to its ratio α- Silicon carbide has attracted much attention due to its higher specific surface area. There is another type of silicon carbide, μ- Silicon carbide is the most stable and can produce a pleasant sound during collisions. However, so far, these two types of silicon carbide have not been commercially applied.

Due to its specific gravity of 3.1 g/cm3 and relatively high sublimation temperature (about 2700 ° C), silicon carbide is very suitable as a raw material for bearings or high-temperature furnaces. It will not melt under any achievable pressure and has relatively low chemical activity. Due to its high thermal conductivity, high breakdown electric field strength, and highest current density, some have attempted to use silicon carbide as a substitute material, especially in the application of high-power semiconductor components. In addition, silicon carbide has a strong coupling effect with microwave radiation, and its high sublimation point makes it suitable for heating metals.

Pure silicon carbide is colorless, but in industrial production, due to the presence of impure substances such as iron, its color is usually brown to black. The rainbow like luster on the surface of the crystal is due to the formation of a protective layer of silica. [10]

SiC is a semiconductor that changes the energy level structure of SiC materials through doping and further regulates their performance. It mainly uses ion implantation to dope atoms such as A, B, and N. Among them, acceptor atoms such as Al are more likely to replace the position of Si in the SiC lattice and form deep main energy levels, thereby obtaining P-type semiconductors; And donor atoms such as N and P are more likely to occupy the lattice position of C and form shallow donor energy levels, thereby obtaining N-type semiconductors [11]. It is worth noting that SiC has a wide doping range (1X1014-1X1019 cm-3) that other wide bandgap semiconductors do not have, and it can easily achieve N-type and P-type doping within this range. For example, the resistivity of 4H SiC single crystals doped with AI is as low as 5 Ω· cm.

Previous: What is silicon carbide?