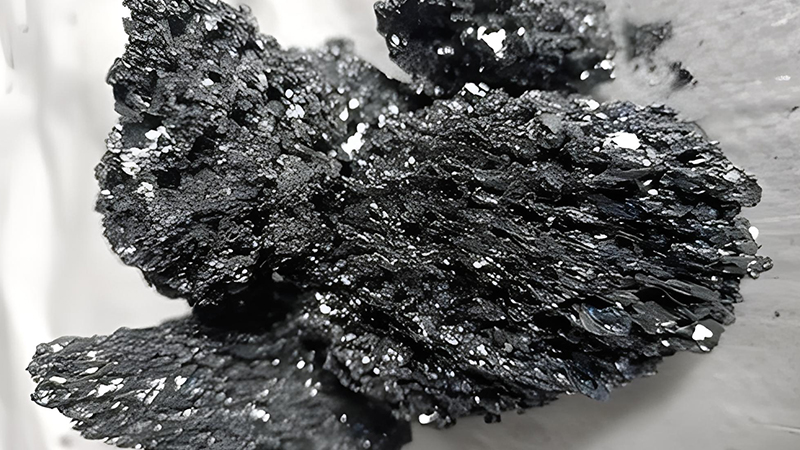

The difference between black silicon carbide and green silicon carbide

Different colors. Black silicon carbide appears black or dark gray, while green silicon carbide appears green or light green.

Different physical properties. The hardness of green silicon carbide is usually higher than that of black silicon carbide, with higher wear resistance and toughness, and better chemical stability, which can resist more chemical corrosion.

Chemical composition and purity. The content of SiC in black silicon carbide is about 98.5%, while the content of SiC in green silicon carbide exceeds 99%, which makes green silicon carbide perform better in terms of hardness and wear resistance.

Different application fields. Black silicon carbide, due to its high toughness and hardness, is commonly used for processing materials with lower tensile strength, such as glass, ceramics, stone, etc. Green silicon carbide, on the other hand, is suitable for grinding materials that require higher precision or hardness due to its higher hardness and purity, such as hard alloy, quartz glass, optical glass, granite, etc.

Prices vary. Due to the higher production cost and raw material purity requirements of green silicon carbide, its price is usually higher than that of black silicon carbide.