Application fields of silicon carbide

Silicon carbide has four main application areas, namely functional ceramics, advanced refractory materials, abrasives, and metallurgical raw materials. The coarse silicon carbide material can already be supplied in large quantities and cannot be considered a high-tech product, while the application of nanoscale silicon carbide powder with extremely high technological content cannot form economies of scale in the short term.

As an abrasive, it can be used as a grinding tool, such as grinding wheels, oilstones, grinding heads, sand tiles, etc.

As a metallurgical deoxidizer and high-temperature resistant material.

High purity single crystals can be used to manufacture semiconductors and silicon carbide fibers.

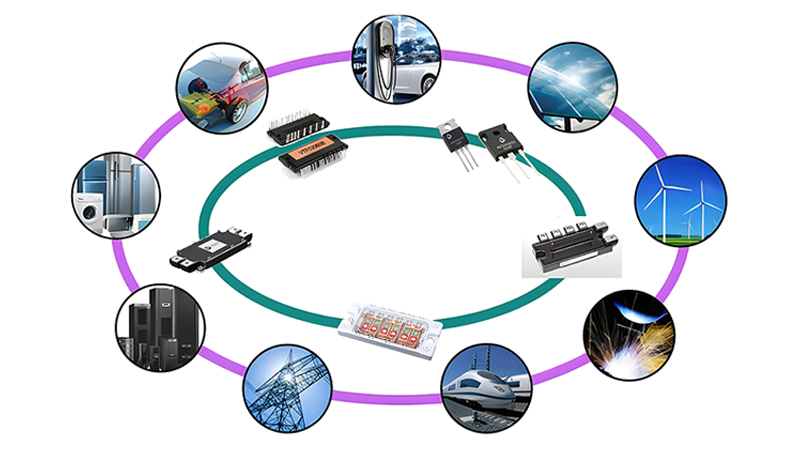

Main use: Used for wire cutting of 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystals, and other materials. Engineering processing materials for the solar photovoltaic industry, semiconductor industry, and piezoelectric crystal industry.

Used in fields such as semiconductors, lightning rods, circuit components, high-temperature applications, ultraviolet detectors, structural materials, astronomy, disc brakes, clutches, diesel particulate filters, fine wire pyrometers, ceramic films, cutting tools, heating elements, nuclear fuel, jewelry, steel, protective equipment, catalytic carrier, etc.

Abrasive grinding tools

Mainly used for grinding and polishing of grinding wheels, sandpaper, sandbelts, oilstones, grinding blocks, grinding heads, grinding paste, monocrystalline silicon and polycrystalline silicon in photovoltaic products, as well as piezoelectric crystals in the electronics industry.

chemical industry

It can be used as a deoxidizer for steelmaking and an improver for cast iron structure. It can also be used as a raw material for manufacturing silicon tetrachloride and is the main raw material in the silicone resin industry. Silicon carbide deoxidizer is a new type of strong composite deoxidizer that replaces traditional silicon powder and carbon powder for deoxidation. Compared with the original process, it has more stable physical and chemical properties, good deoxidation effect, shortened deoxidation time, saved energy, improved steelmaking efficiency, improved steel quality, reduced consumption of raw and auxiliary materials, reduced environmental pollution, improved labor conditions, and improved comprehensive economic benefits of electric furnaces, all of which have important value.

"Three resistant" materials

Silicon carbide has the characteristics of corrosion resistance, high temperature resistance, high strength, good thermal conductivity, and impact resistance. On the one hand, silicon carbide can be used for various smelting furnace linings, high-temperature furnace components, silicon carbide plates, lining plates, support components, casks, silicon carbide crucibles, etc.

On the other hand, it can be used as high-temperature indirect heating materials in the non-ferrous metal smelting industry, such as vertical distillation furnaces, distillation furnace trays, aluminum electrolysis tanks, copper melting furnace linings, arc plates for zinc powder furnaces, thermocouple protection tubes, etc; Used for producing advanced silicon carbide ceramic materials that are wear-resistant, corrosion-resistant, and high-temperature resistant; It can also be made into rocket nozzles, gas turbine blades, etc. In addition, silicon carbide is also one of the ideal materials for solar water heaters on highways, aviation runways, etc.

Thermal conductive materials

The thermal conductivity of SiC materials, like most dielectric solids, is mainly influenced by the transmission of thermoelastic waves (called phonons). The thermal conductivity of SiC materials mainly depends on: 1) the quantity of sintering aids, stoichiometric ratio, chemical properties, and related grain boundary thickness and crystallinity; 2) Grain size; 3) The types and concentrations of impurity atoms in SiC crystals; 4) Sintering atmosphere; 5) Heat treatment after sintering, etc. SiC has excellent properties such as high thermal conductivity, large bandgap width, high electron saturation migration rate, and high critical breakdown electric field. Its excellent comprehensive performance makes up for the shortcomings of traditional semiconductor materials and devices in practical applications, and has broad application prospects in fields such as electric vehicles and mobile communication chips. Due to its higher reliability, higher operating temperature, smaller size, and higher voltage endurance, SiC can be applied to power devices such as main drive boards, on-board chargers, and power modules, greatly improving efficiency and increasing the endurance of electric vehicles. At the same time, SiC has good thermal conductivity, and the use of SiC semiconductor power devices can reduce battery size and more effectively convert energy, thereby reducing the cost of assembly devices. SiC ceramics, as a high-performance structural ceramic material, have excellent thermal properties and can be widely used in high-temperature resistance, heating, and heat exchange industrial fields.

steel

By utilizing the characteristics of corrosion resistance, thermal shock resistance, wear resistance, and good thermal conductivity of silicon carbide, it has been used in the lining of large blast furnaces to improve its service life.

Metallurgical beneficiation

Silicon carbide has a hardness second only to diamond and strong wear resistance. It is an ideal material for wear-resistant pipes, impellers, pump chambers, cyclones, and ore hopper linings. Its wear resistance is 5-20 times longer than the service life of cast iron and rubber, and it is also one of the ideal materials for aviation flight runways.

energy conservation

By utilizing good thermal conductivity and stability as a heat exchanger, fuel consumption is reduced by 20%, fuel is saved by 35%, and productivity is increased by 20-30%.

The particle size and composition of abrasives shall comply with GB/T2477-83. The determination method for abrasive particle size composition shall be in accordance with GB/T2481-83.

jewelry

Synthetic Moissanite, also known as synthetic mosonite or synthetic carbon silicon stone (chemical composition SiC), has a dispersion of 0.104, is larger than diamond (0.044), a refractive index of 2.65-2.69 (diamond 2.42), and has the same diamond luster as diamond. It has a stronger "fire color" and is closer to diamond than any previous imitation.